Worksite Essentials

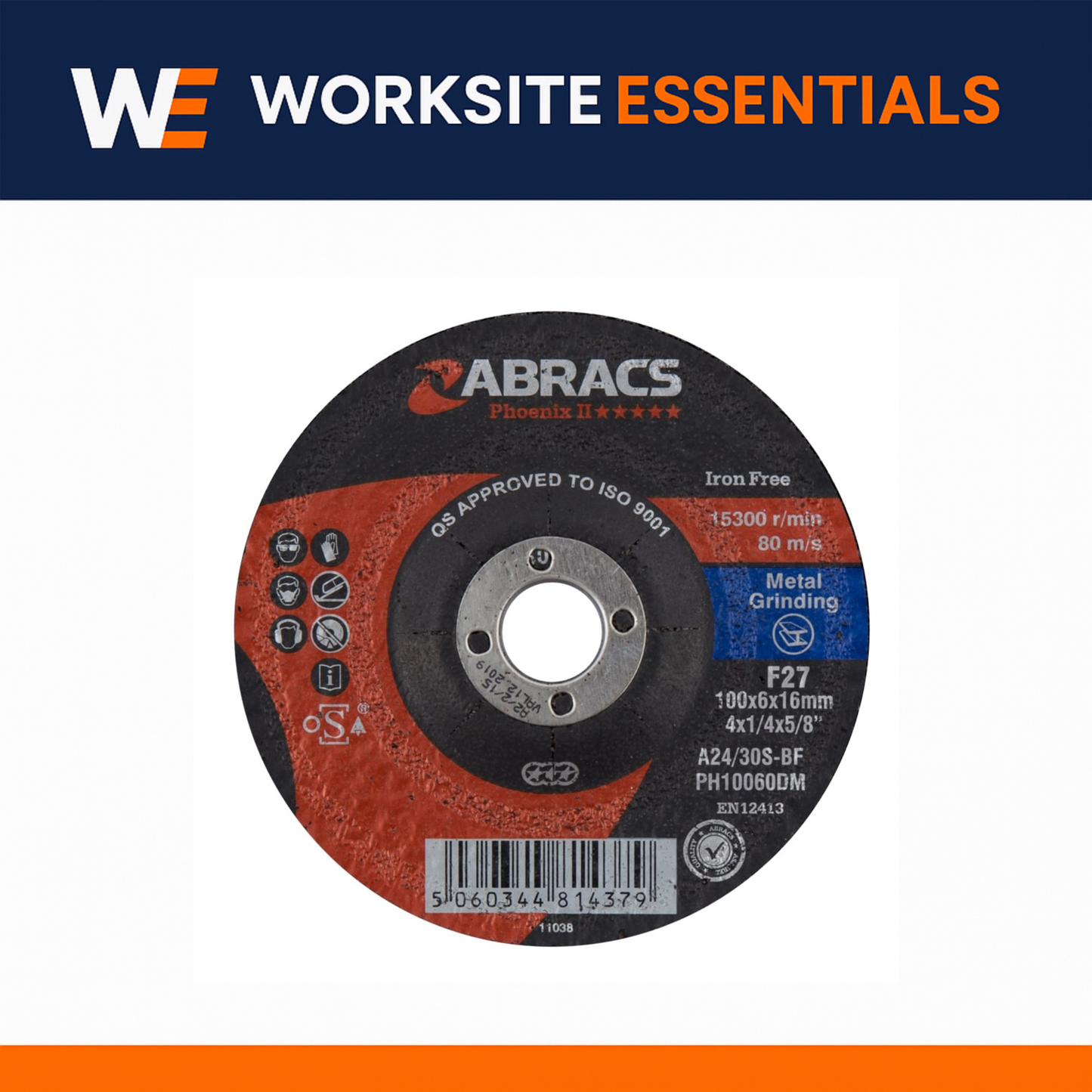

Metal Grinding Discs for Angle Grinders – Abracs Phoenix Heavy-Duty Abrasive Wheels (EN12413 / O.S.A. Approved)

Metal Grinding Discs for Angle Grinders – Abracs Phoenix Heavy-Duty Abrasive Wheels (EN12413 / O.S.A. Approved)

Couldn't load pickup availability

Power through metal with precision using Abracs Phoenix Metal Grinding Discs — professional-grade European-manufactured abrasive wheels engineered for steel fabrication, weld removal, and surface preparation.

Every disc is built to O.S.A. Safety Standards and marked with EN12413 certification, guaranteeing consistent quality, strength, and operator safety.

The resin-bonded, reinforced design offers exceptional material removal, long service life, and cooler grinding, helping you finish jobs faster and cleaner.

From light surface blending to aggressive stock removal, Phoenix Metal Grinding Discs deliver ultimate performance, reliability, and control for trade and industrial use.

🔹 Key Features

- Heavy-Duty Abrasive Formulation: Rapid stock removal and consistent finish on mild, structural & stainless steel.

- Extended Disc Life: Premium European grain blend resists wear and maintains cutting power.

- Precision Balance: Reduced vibration for smoother, safer grinding.

- O.S.A. & EN12413 Certified: Full compliance with European safety and performance standards.

- Trade Quality Construction: Trusted by fabricators, welders & engineers nationwide.

- Fits All Standard Angle Grinders: 22.23 mm bore for 115 mm–230 mm machines.

⚙️ Technical Specifications

|

Specification |

Detail |

|

Application |

Metal Grinding Only |

|

Material Type |

Resin-Bonded, Reinforced Abrasive Disc |

|

Suitable Materials |

Mild Steel, Stainless Steel (Inox), Carbon & Structural Steel, Cast Iron |

|

Standards |

O.S.A. Certified / EN12413 Compliant |

|

Bore Size |

22.23 mm |

|

Available Diameters |

115 mm / 125 mm / 180 mm / 230 mm |

|

Max Speed |

Up to 13 300 RPM (size dependent) |

|

Origin |

European Manufactured |

|

Brand |

Abracs Phoenix Range |

⚒️ Applications

- Weld removal and edge cleaning

- Surface preparation and deburring

- Steel fabrication and maintenance workshops

- General industrial and engineering use

💡 Usage Tips

- Allow grinder to reach full speed before contacting the workpiece.

- Maintain steady, moderate pressure — let the disc cut, don’t force it.

- Always use eye, ear & hand protection and check RPM rating = tool speed.

- Store discs in a dry area to prevent moisture damage.

Share